The ambitious hybrid power project was brought to fruition by the cooperative work and expertise of B2Gold, Suntrace and BayWa r.e., along with feasibility studies performed using HOMER Pro.

Since 2017, international gold producer B2Gold’s off-grid Fekola Gold Mine in Mali, West Africa, has generated electricity with an on-site thermal power plant. Then in 2019, the operation’s heavy dependence on fossil fuel took a turn toward cleaner energy. That’s when mine owner B2Gold joined forces with renewable energy advisers Suntrace and global renewable energy company BayWa r.e. to incorporate solar plus energy storage into the plant’s power supply.

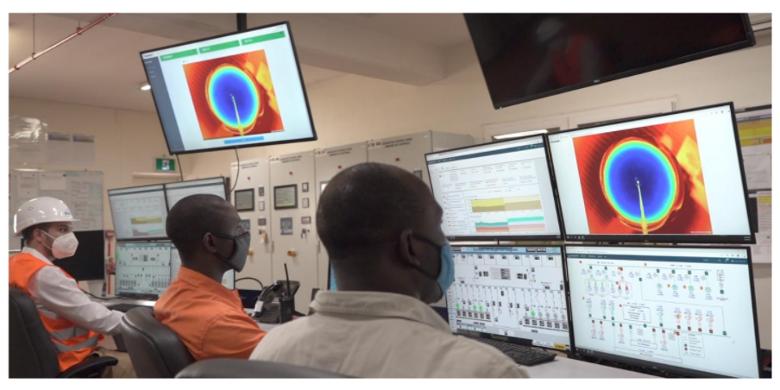

The three entities worked together to develop, install and deploy the solar system and battery storage and then integrate it into the existing setup. The hybrid system was successfully commissioned in March 2021 and has operated at full solar plant capacity since July 2021. It includes a 30-megawatt (MW) solar plant plus 15.4 megawatt-hours (MWh) battery storage and the existing 64 MW thermal plant. Currently, the Fekola Gold Mine installation is the world’s largest off-grid mining hybrid power system, according to BayWa r.e.

Following is an interview with Thorsten Althaus, project manager at BayWa r.e. Solar Projects. He told Microgrid News about the project and the role UL’s HOMER® Pro played in its development.

Microgrid News (MN): What was the impetus for this ambitious project?

Thorsten Althaus (TA): Fekola mine started gold production in 2017 and generated all electricity required for its operations with heavy fuel oil generators in an on-site thermal plant. The mine is always looking for opportunities to improve efficiencies and lower operating costs, and owner B2Gold also wanted their project to support decarbonization, local job creation and sustainability. Last but not least, B2Gold followed a simple economical imperative: Replacing oil with renewable energies simply lowered their energy bill, short term and long term. It is already cheaper today and partially protects B2Gold from potential oil price increases in the future.

MN: How did you become involved?

TA: B2Gold had already implemented a solar plant at one of its other mines before, so they already had some experience with the technology and how a hybrid plant can reduce electricity costs. They were keen on exploring this option for Fekola mine as well, which is how we got involved with the feasibility study.

Suntrace, a Hamburg-based renewable energy adviser we’ve successfully worked with in the past, introduced this opportunity to us because of our expertise in hybrid systems. We soon decided to team up, first for a feasibility study and then to implement the project at the mine.

MN: Your team conducted the feasibility study in early 2019, and the project was then approved quickly. To what do you attribute this success?

TA: I think we did a very good job showing an attractive cost and CO2 savings potential in the feasibility study. But of similar importance was our clear depiction of how the savings would be achieved. We showed how solar, battery and gensets would interact in the hybrid system and ensure a stable power supply, which is indispensable to life on a mining site and, therefore, extremely important and critical. Additionally, a clearly defined operational concept, which we jointly developed in close collaboration with the thermal power plant’s operators, gave B2Gold the comfort to move ahead with this complex project.

MN: Please describe the feasibility study and the detailed information you were able to provide. What role did HOMER Pro play in this?

TA: We used HOMER Pro for the simulations in the feasibility study. First, we created a general evaluation of scenarios with and without battery storage to outline different options for implementing a solar plant at the mine. Based on this preliminary review, we chose the most suitable approach for the customer, and with that settled, we went into the detailed modeling.

During a site visit in Mali, we had developed a good understanding of the thermal power plant, particularly its operating limits, ramping capabilities and dispatch rules. With this information, we created a concept of integrating a large amount of renewable power into the existing system. Using a battery storage system would keep everything safe and stable while shutting down half of the thermal power plant on sunny days.

Since a few of our operating requirements could not be covered with the microgrid controllers included in HOMER, we used the software’s Matlab link to essentially code our energy management system, which was tailored to this project. We tried various component sizes in HOMER and compared the results. This enabled us to finetune and optimize the system configuration. The control concept developed in the feasibility study was later implemented in the energy management system deployed on-site by our battery vendor, Wärtsilä.

MN: Looking back, how did completing this project impact BayWa r.e.?

TA: Integrating a large renewable energy plant into a small, isolated and constrained grid is challenging. This project allowed us to show that we are well capable of handling such complex applications. It’s been fantastic teamwork with our partners B2Gold and Suntrace and a great experience to work on this landmark project, which required such a unique control and energy management system. I am very proud that it is efficiently and reliably working the way we designed it in such a system-critical and extreme environment. It is the proof of renewable energies being able to take over the responsibility for system stability, at lower cost in two aspects: economically and for the environment.

About BayWa r.e.

At BayWa r.e., we r.e.think energy — how it is produced, stored and can be best used to enable the global renewable energy transition that is essential to the future of our planet. We are a leading global developer, service supplier, distributor and solutions provider and have brought over 4 GW of energy online and manage over 10 GW of assets. We are also an Independent Power Producer with an expanding energy trading business.

BayWa r.e. works with businesses worldwide to provide tailored renewable solutions. Operating 100% carbon neutral, we are also committed to our own sustainability journey. Every day, we are working hard to actively shape the future of energy in a diverse, equitable and inclusive workplace. Our shareholders are BayWa AG, a €17.2 billion global business, and Energy Infrastructure Partners, a leader in energy infrastructure investment.

UL Solutions’ HOMER® Pro is the leading pre-feasibility design software for modeling microgrids, with more than 250,000 users in more than 190 countries. It provides engineering and financial analyses of remote, off-grid and grid-tied complex distributed energy systems, helping reduce financial risk for owners and developers. Learn more about HOMER Pro and download a complimentary trial.