Hydrogen can help decarbonize hard-to-abate, energy- and carbon-intensive industrial processes, long-haul transporting, and ammonia production. But making hydrogen requires a significant amount of electricity. When the hydrogen (H2) is not green, the carbon footprint of producing the hydrogen counteracts its value as a clean fuel source.

Green hydrogen delivers clean energy with only water and heat as a byproduct. Because of its value in decarbonizing and reducing the cost of energy-intensive processes, green hydrogen is seeing renewed and intensified focus as the path to fully decarbonizing energy use worldwide.

Incorporating software tools into the design of your hydrogen projects can help you evaluate and demonstrate the technical and economic value of green hydrogen.

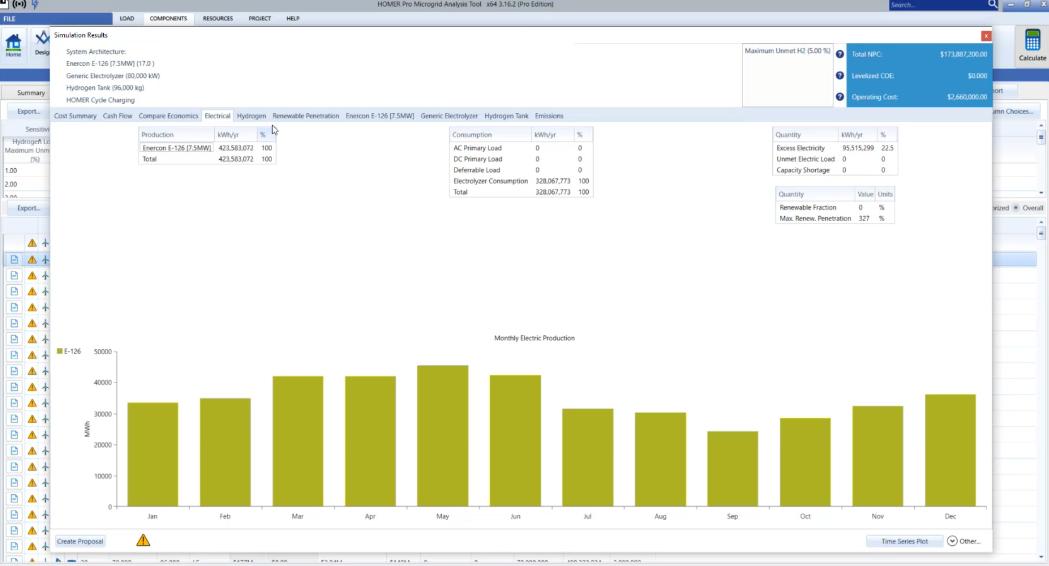

HOMER Pro software offers capabilities to help you speed and simplify energy modeling for large industrial processes, fuel cells, remote off-grid operations or any system with hydrogen production, storage or consumption. Below is an overview of some of the capabilities that can help you develop the least-cost solution.

Electrolyzer modeling

According to Energy.gov, electrolysis can produce carbon-free hydrogen from renewable and nuclear resources by using electricity to split water into hydrogen and oxygen. The reaction takes place in an electrolyzer. HOMER Pro software helps design system configurations to produce green hydrogen and power green hydrogen-powered manufacturing plants by enabling you to:

- Specify energy and hydrogen consumption requirements.

- Determine the capacity and efficiency of the electrolyzer.

- Produce green hydrogen from wind- or solar-generated electricity

Reformer modeling

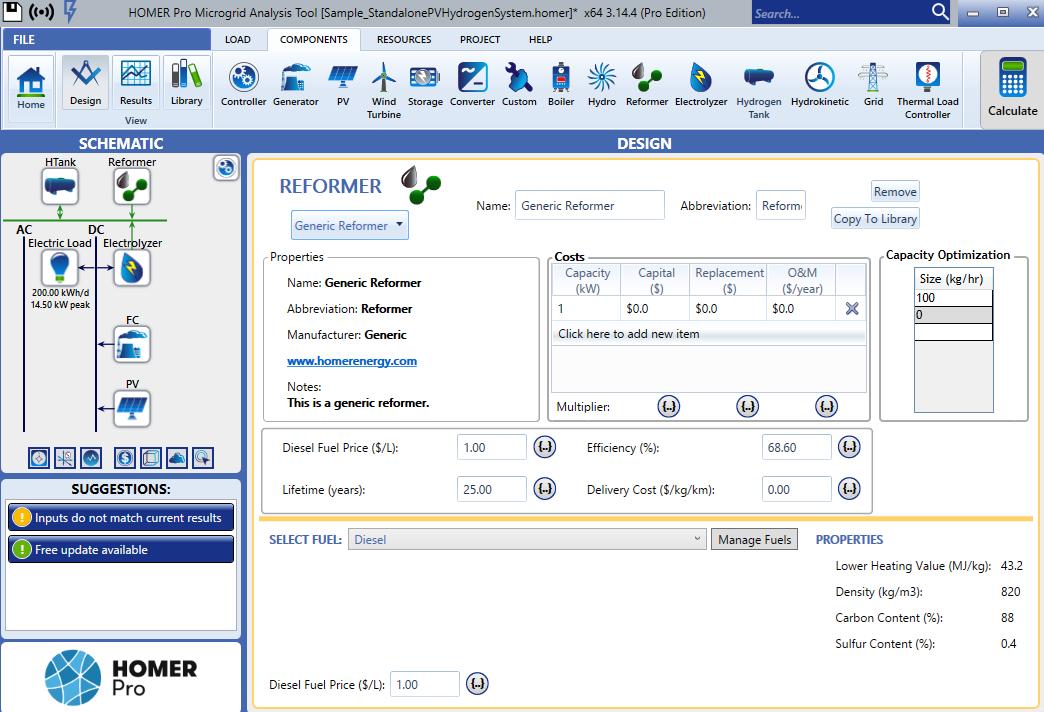

Today, hydrogen systems often use gray or blue H2, made by reacting methane gas at high temperatures in a reformer. While the clean energy goal is green H2, increased use of gray or blue hydrogen may come first. HOMER Pro software offers a reformer component, enabling the modeling of hydrogen produced from methane gas, including:

- Capital purchase and replacement costs.

- Operating and maintenance costs.

- Properties such as size, efficiency and the fuels used to operate the reformer.

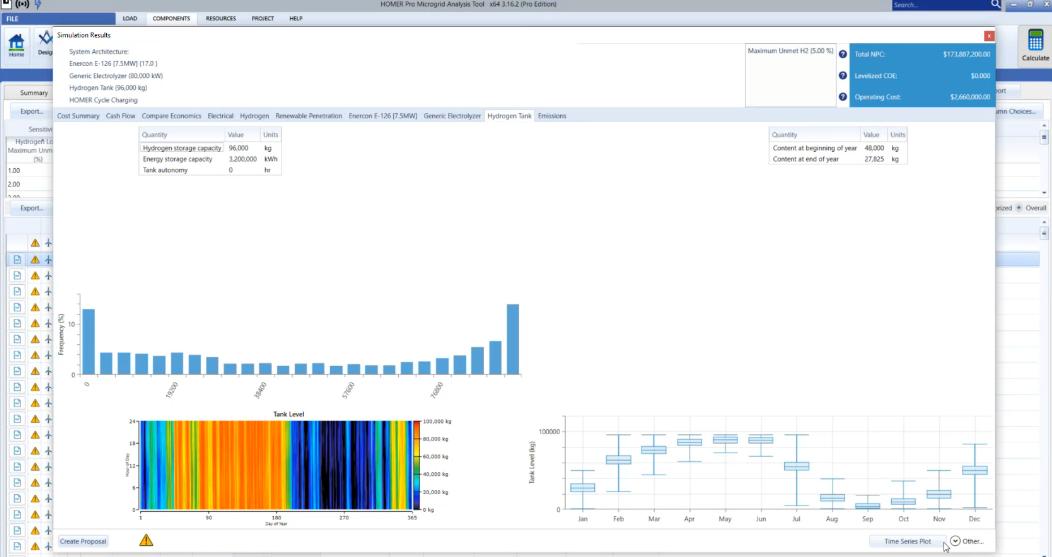

Hydrogen tank

You can compare the costs of storing energy in hydrogen or batteries and its value in the dispatch strategy for renewable energy. To model a hydrogen tank, input data for the hydrogen storage tank, including the expected tank size and costs, its expected lifetime, and initial and year-end tank levels.

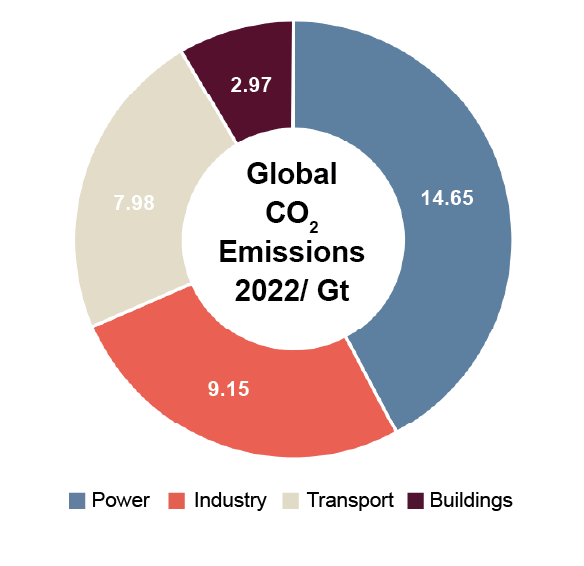

Green hydrogen is considered critical to clean energy goals

Decarbonizing energy-intensive uses has been identified as critical to meeting clean energy goals. The adoption of more aggressive decarbonization goals has heightened investment interest in retrofitting existing plants and building new plants equipped with green hydrogen capabilities. The installed capacity of electrolyzers worldwide grew by more than 20% in 2022. It could reach almost three gigawatts (GW) by the end of 2023 — four times the total capacity of 2022, according to data from the International Energy Agency (IEA).

Source: IEA, Global CO2 emissions by sector, 2019-2022, IEA, Paris, IEA. Licence: CC BY 4.0

Learn more about HOMER Pro modeling software